News

What is new in Industrial IoT and at TWTG? Get the news here or via our social media.

The Latest News

-

IMI launches new NEON Sonic sensor for steam trap monitoring

Content type:Press ReleaseCategories:NEONRotterdam, November 2025 IMI is expanding its NEON sensor range with a combined sound and temperature sensor for the acoustic wireless monitoring of steam traps and pressure/safety relief valves (PRV/SRV) as steam-reliant industries globally grapple with steam condensation and trap failures. The LoRaWAN-enabled NEON Sonic can measure sound pressure levels from 15 to 80 kHz […]

Published on: -

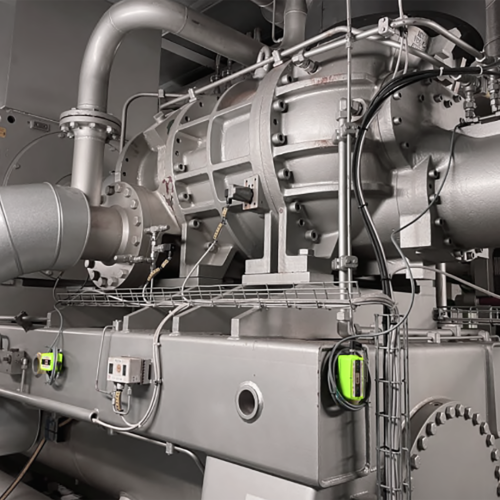

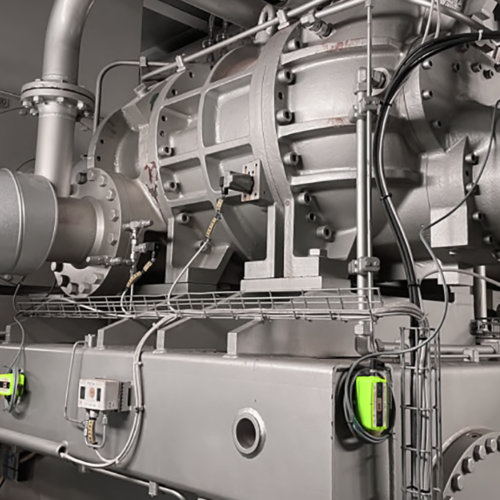

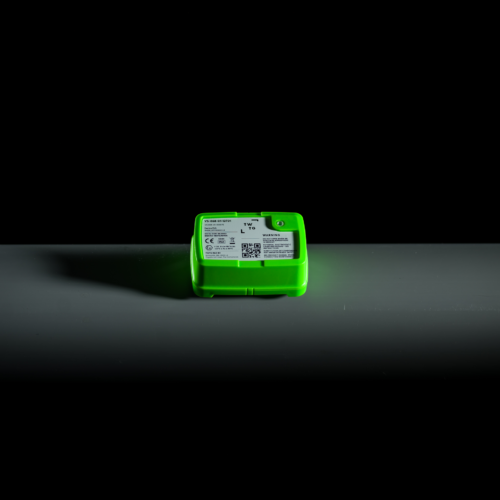

How the NEON non-Ex Sensor Variants Can Unlock a New Era of Manufacturing Efficiency

Content type:ArticleCategories:NEONYou cannot manage what you cannot measure.[i] This quote from Peter Drucker essentially explains condition-based monitoring (CBM), which uses real-time data to assess the health of industrial equipment and determine when maintenance should be conducted. It’s a simple idea that continues to unlock significant, measurable improvements. IMI TWTG’s original NEON technology range applies to hazardous environments […]

Published on:

I-IoT News Directly in Your Inbox

Stay up to date on the latest I-IoT news, use cases and product developments.

All News

-

Actility Names TWTG its Most Innovative and Valued Partner in the Benelux

Content type:Press ReleaseCategories:EnergyParis, April 2025 Actility, a global leader in Industrial IoT connectivity, has named TWTG its Most Innovative and Valued Partner in the Benelux. The announcement marks a significant milestone in the companies’ ongoing partnership, built on mutual technical expertise, shared commitment to industrial digitalization, and successful joint initiatives. “TWTG has consistently demonstrated not only technical […]

Published on: -

LoRaWAN®: Security Built-in

Content type:ArticleCategories:EnergyWhy LoRaWAN Is The Industrial I-IoT Enabler You Can’t Ignore (3/5) Discover in our third article of this series how LoRaWAN’s built-in capabilities can be utilized to ensure a secure deployment. Key Takeaways Multiple Layers Of Robust Security To ensure that the network is protected and your data is kept secure, LoRaWAN has multiple security […]

Published on: -

Downtime is Money

Content type:ArticleCategories:EnergyThe Primary Impact of Predictive Maintenance. The impact of predictive maintenance across various industry sectors has been extensively documented in recent years. This article explores how manufacturing companies can achieve significant cost savings by minimizing downtime, ultimately improving their financial investments. We present practical examples and key statistics that highlight the financial benefits of permanent […]

Published on: -

LoRaWAN®: Long Battery Life

Content type:ArticleCategories:EnergyWhy LoRaWAN Is The Industrial I-IoT Enabler You Can’t Ignore (2/5) Learn in our second article of this series how to leverage the low-power capabilities of LoRaWAN devices to your advantage. Key Takeaways LoRaWAN Technology Has Extremely Long Battery Life The ultra-low-power design of LoRaWAN devices allows them to operate for extended periods without any […]

Published on: -

IMI Acquires TWTG!

Content type:Press ReleaseWe are very pleased to announce that specialist engineering company IMI has acquired TWTG. The strategic acquisition by IMI plc will empower us to expand our Industrial IoT capabilities. Please find the full Press Release here: 31 October 2024 Press Release IMI Acquires TWTG to Expand Industrial IoT Capabilities IMI Plc, has announced the acquisition […]

Published on: -

Better Battery Monitoring

Content type:White PaperCategories:EnergyNEONMaximizing Efficiency with TWTG Battery Life Prediction and Monitoring. Introduction Effective battery monitoring is crucial in large-scale industrial deployments to ensure sensor networks operate continuously and efficiently. Accurate battery monitoring helps reduce downtime and maintenance costs, enabling asset managers to manage resources better and maintain operational reliability. The Need for Accurate Battery Monitoring Challenges with […]

Published on: -

Next Step in Global Expansion TWTG

Content type:NewsTWTG Expands into Africa with Advanced I-IoT Devices for Industrial Enhancement. TWTG, a leader in Industrial Internet of Things (I-IoT) solutions, announces its expansion into Africa, introducing cutting-edge NEON devices across key sites in the Republic of Congo, Angola, and South Africa. TWTG’s NEON sensors, with robust IECEx/ATEX certification, ensure the highest safety and efficiency […]

Published on: -

NEON Valve Sensor Installation Explainer Videos

Content type:NewsCategories:NEONIn TWTG’s new series of explainer videos, with English voiceover and subtitles in English, Arabic, French, and Spanish, we show how easy it is to install NEON Sensors. Following videos on the NEON Vibration Sensor, we will now demonstrate the quick and easy installation of the NEON Valve Sensor with Universal Bracket. For further detailed information please […]

Published on: -

Machine Fault Indication with NEON’s ActiveMFI

Content type:White PaperCategories:NEONRevolutionizing Predictive Maintenance with NEON ActiveMFI Technology. In a modern industrial plant, the reliability and performance of every piece of machinery are crucial in avoiding unscheduled, costly downtime. Modern Technologies, particularly the Industrial Internet of Things (I-IoT) and predictive maintenance are leading the way in keeping facilities operational. In this trajectory, TWTG developed its sensor […]

Published on: -

Aramco and TWTG Sign Agreement to Accelerate Digital Transformation

Content type:Press ReleaseCategories:EnergyNEONSolidRedMoU Signed to Drive Digitalization with NEON IoT Sensors in Saudi Arabia’s Industrial Sector. Rotterdam, 21 February 2024. TWTG, the Dutch pioneer in Industrial Internet of Things (I-IoT) solutions and Aramco, one of the world’s leading integrated energy and chemicals companies, have taken a significant stride toward advancing Aramco’s digital transformation of Saudi Arabia’s industrial […]

Published on: -

TWTG Insight Seminar Kingdom of Saudi Arabia

Content type:NewsCategories:EnergyMeet the LoRaWAN and Engineering Experts from Naizak, Actility, and TWTG. Our first-ever Insight Seminar in the Kingdom of Saudi Arabia hosted together with Naizak and Actility under the theme of ‘LoRaWAN and Engineering Excellence’ was a tremendous success. The seminar entailed three master classes addressing how to make implementing LoRaWAN solutions easy and accessible. […]

Published on: -

New Universal Valve Bracket

Content type:Press ReleaseCategories:NEONThe NEON QT Valve Sensor now enables fast deployment without downtime or need to calibrate. Rotterdam, July 2, 2024 – In a significant stride towards revolutionizing industrial operations, TWTG today announced the release of its newly redesigned NEON Valve Sensor. This launch marks a pivotal development in how industrial engineers monitor and manage valve activities, ensuring […]

Published on: -

Successful collaboration within an IoT ecosystem

Content type:NewsDeveloping and testing devices for Eneco’s large-scale rollouts – a fruitful collaboration. Rotterdam, 9 April 2024. Based on the Article (in Dutch) published by AMIS Conclusion Successful collaboration within an IoT ecosystem How an ‘unplanned relationship’ flourished into a fruitful collaboration: Understanding how an arranged alliance can ultimately yield something very beautiful. We speak with John Tillema, CTO […]

Published on: -

Sensor Fusion Technology with NEON TimeSync – White Paper

Content type:White PaperCategories:NEONAdvancing Industrial Operations through Sensor Fusion Technology with NEON TimeSync. In early 2024, TWTG will elevate its NEON sensor range by integrating advanced sensor fusion technology. This significant technological update will introduce two key features: TimeSync and EventSync, both designed to enhance data accuracy and synchronization across industrial applications. Our White Paper, downloadable in PDF format, […]

Published on: -

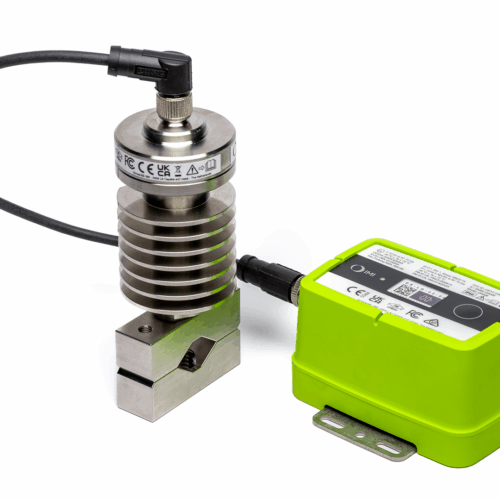

NEON Vibration Sensor Installation Explainer Videos

Content type:ArticleCategories:NEONDemonstrating the quick and easy installation of the NEON Vibration Sensor. Welcome to TWTG’s new series of explainer videos. In these videos, with English voiceover and subtitles in English, Arabic, French, or Spanish, we will demonstrate the quick and easy installation of the NEON Vibration Sensor. For further detailed information please consult the manual. Or contact […]

Published on: -

Continuous Innovation at TWTG – NEON Sensor Fusion

Content type:ArticleCategories:NEONSolidRedIntroducing TWTG’s Advanced Sensor Fusion Technology: A Leap Forward in Intelligent Predictive Maintenance. Rotterdam, March 18, 2024. TWTG, a key player in Industrial Internet of Things (I-IoT) solutions, announced the launch of new sensor fusion technology for compatible sensors within their NEON product range. Sensor fusion technology represents a significant stride in I-IoT and the industries […]

Published on: -

TWTG and NAIZAK form partnership to provide I-IoT solutions in Saudi Arabia and beyond

Content type:Press ReleaseCategories:EnergyMiddle Eastern Industrial customers will have easy access to NEON products. Rotterdam, 21 November 2023. TWTG, the Dutch pioneer in Industrial Internet of Things (I-IoT) solutions, and Naizak, the well-established distributor of technology solutions, have signed a partnership agreement at the inaugural Global Industrial Internet of Things Summit (GIITS) in Dammam, Saudi Arabia. The partnership […]

Published on: -

LoRaWAN for Industry – Five Factors

Content type:ArticleCategories:EnergyWhy LoRaWAN Is The Industrial I-IoT Enabler You Can’t Ignore. In this article, TWTG covers the basic questions clients ask when first starting with LoRaWAN, exploring the five key areas engineers need to assess when evaluating wireless technologies for their future roadmap. In addition, we consider the advantages of LoRaWAN and discuss the benefits of […]

Published on: -

TWTG Insight Seminar USA

Content type:NewsCategories:EnergyNEONMeet the LoRaWAN Experts in North America with Actility, TEKTELIC, and TWTG. On September 12th, 2023, the second Insight Seminar organized by Actility, TEKTELIC, and TWTG took place, this time in Houston, Texas. And we are happy to say that it was an immense success! This second seminar followed the well-received first-ever TWTG Insight Seminar […]

Published on: -

LoRaWAN®: No Vendor Lock-in

Content type:ArticleCategories:EnergyWhy LoRaWAN Is The Industrial I-IoT Enabler You Can’t Ignore (1/5). Learn in our first article of this series about the perils of vendor lock-in, and LoRaWAN’s open ideology and limitless IoT possibilities. Key Takeaways No Vendor Lock-in brings Autonomy The first and often the most overlooked advantage of having no vendor lock-in is the […]

Published on: -

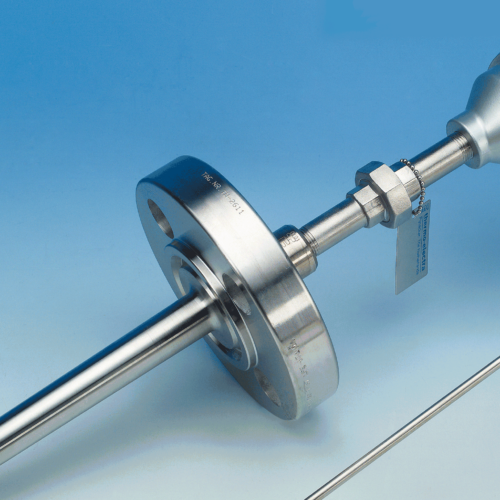

TWTG and Thermo-Electra partners in Wireless Temperature Measurement

Content type:Press ReleaseCategories:NEONIndustrial customers worldwide benefit from bundled expertise, bespoke tooling, and improved support. Rotterdam, 28 March 2023. TWTG and Thermo-Electra are excited to announce they have formed a partnership, which will combine their expertise in wireless temperature measurement solutions. The partnership will enable both companies to collaborate and leverage each other’s strengths to create new business […]

Published on: -

SolidRed receives Innovation Technology Award

Content type:Press ReleaseCategories:SolidRedSolidRed is awarded for revolutionizing the industry, following NEON’s win at a previous award show. Rotterdam, 16th March 2023. Last night, at the Schiecentrale in Rotterdam, TWTG’s SolidRed software suite received an Innovative Technology Tank Storage Award for revolutionizing the industry. At the annual ceremony of the Tank Storage Awards, hosted by Tank Storage Magazine […]

Published on: -

TWTG Insight Seminar – Meet the Experts

Content type:NewsCategories:NEONMeet the LoRa Experts with Actility, TEKTELIC, and TWTG. On March 13th, 2023, TWTG, Actility, and TEKTELIC organized the first Insight Seminar under the theme of ‘Meet the LoRaWAN Experts’. This seminar provided attendees with the opportunity to meet some of the industry’s leading experts in the Industrial IoT space. The event featured three sessions […]

Published on: -

Actility and TWTG partner up to strengthen I-IoT solutions

Content type:Press ReleaseCategories:NEONCustomers benefit from ready-to-use connectivity and easy integration. Rotterdam & Paris, 2nd February 2023. Actility and TWTG are excited to announce they have formed a partnership, which will open opportunities for more and wider LoRaWAN® applications by offering partners and customers clear benefits. Wirelessly connecting devices to the internet and managing communication between end-node devices […]

Published on: -

TWTG receives North America Certification

Content type:Press ReleaseCategories:EnergyNEONFCC, FM, and IC certification for high-demand NEON devices. Rotterdam, 9th January 2023. After a strong reception in Europe, TWTG’s latest set of NEON devices is now ready to be rolled out in North America. TWTG has received FCC, FM, and IC certification for both the NEON Temperature Transmitter and the NEON Vibration Sensor, opening […]

Published on: -

Start with Temperature Sensors

Content type:ArticleCategories:EnergyNEONTempted to try LoRaWAN but unsure where to begin? Maybe with a temperature sensor or two. In this article, John Tillema, Chief Technology Officer of TWTG, covers the basics of LoRaWAN and reflects on the questions most heard and the fundamental ones often overlooked. John shares the first steps to take when evaluating this new technology […]

Published on: -

Shell and TWTG Sign Global Software Agreement

Content type:Press ReleaseCategories:EnergyNEONSolidRedInterpreting vibration data from LoRa sensors paves the way for smarter Shell sites globally. Rotterdam, 26th September 2022. Not a company to stand still for long, Dutch I-IoT solution provider TWTG has now secured an enterprise framework agreement to supply their vibration analytics solution to Shell Information Technology International BV. Only months after delivering 2,500 wireless NEON […]

Published on:

Connect with TWTG on Social Media:

Stay up-to-date with us on LinkedIn

Check out our Vimeo channel for the latest videos