How to improve steam trap reliability and energy efficiency through ultrasonic monitoring

Steam traps are small components with a big impact. Found across the chemical, oil and gas, and energy industries, they discharge condensate from steam systems. When they fail, either by blocking or leaking, the consequences can be costly, including wasted energy, reduced efficiency, and higher maintenance expenditures.

Our NEON Sonic sensors offer a modern, data-driven approach to steam trap management. Using ultrasonic and temperature measurements, they continuously monitor each trap’s condition, detect failures early, and help operators plan maintenance more effectively, all without manual inspections or operational interruptions.

Improving reliability in complex chemical environments

Sites manufacturing chemicals often contain thousands of steam traps, each one vital in maintaining process stability and energy efficiency. Traditionally, these devices are inspected manually, often by external contractors visiting once every year.

While effective in principle, this approach creates significant gaps between assessments, meaning failures may go undetected for months. A single leaking steam trap can result in hundreds to thousands of pounds in wasted energy each year. When multiplied across dozens or even hundreds of traps, the financial impact rises sharply.[1]

Manual inspection also presents safety and logistical challenges. Many traps are difficult to access or located in hazardous areas, requiring specialised personnel and shutdown coordination. With growing sustainability targets across the chemical sector, production site operators need a more continuous, automated solution.

NEON Sonic: Continuous insight through ultrasonic and temperature sensing

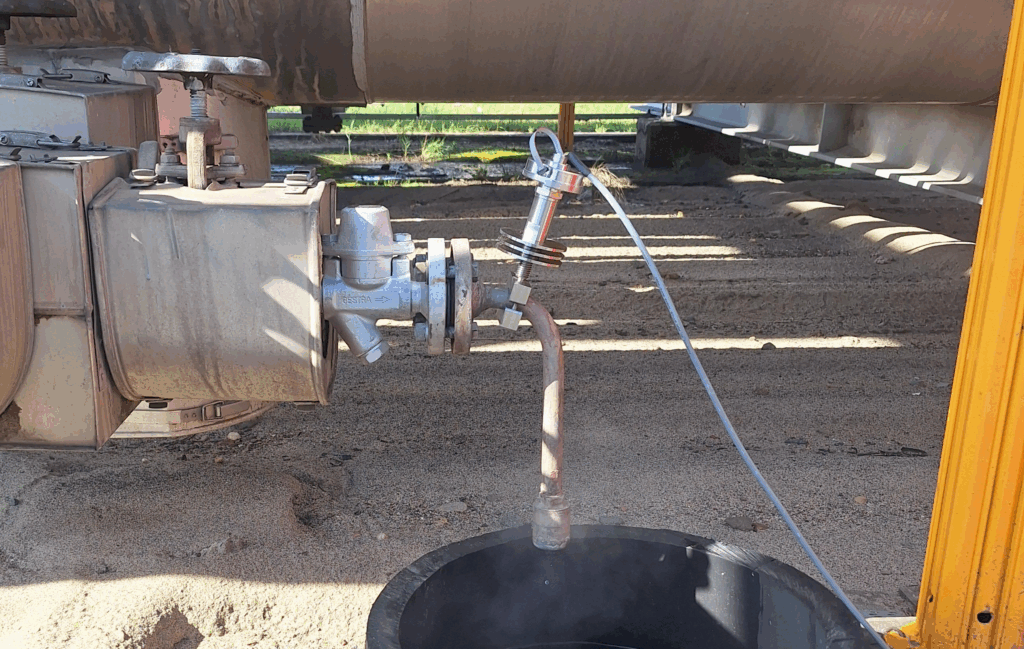

We deployed our NEON Sonic sensors across selected steam traps on a major chemical site to address this challenge. Each device is mounted on the condensate return pipe adjacent to the trap and can be installed in live environments without interrupting operations.

NEON Sonic combines two key measurement principles, ultrasonic activity and temperature, to deliver a far more accurate assessment of steam trap condition than temperature-only systems.

While most monitoring solutions rely on either external temperature sensors, costly and fragile, or on software-estimated temperatures after a heat standoff, their accuracy collapses in real-world conditions. NEON Sonic overcomes this by directly measuring the true operating temperature at the pipe itself, in combination with the ultrasonic signatures. This dual-parameter approach enables reliable leak detection and identification of blocked traps across all trap types and process conditions, delivering continuous, dependable insight even in high-temperature environments.

By analysing sound pressure levels (SPL) and temperature data, engineers can remotely verify trap status and detect abnormalities as soon as they occur. This provides a more precise and universal monitoring method, equipping operators to act before performance losses escalate.

How NEON Sonic detects faults

The sensor continuously measures the temperature of the condensate return pipe and the surrounding ambient environment, along with the intensity of ultrasonic activity within the line.

When a steam trap is blocked, condensate accumulates, and the pipe cools down. As a result, the pipe temperature drops close to ambient temperature, and ultrasonic activity is minimal.

Conversely, as live steam escapes through the outlet, a leaking trap produces a noticeably higher pipe temperature and strong ultrasonic signals. Under regular operation, the sensor detects moderate ultrasonic activity and stable temperature differentials. This combined analysis allows maintenance teams to pinpoint specific fault types instantly, with a high degree of confidence.

A configurable hold-off time can be set for cold state measurements to avoid false positives when bypassing steam traps or when the process is not running. Furthermore, the system relies on pattern recognition across multiple measurements rather than one data point.

This helps to prevent false positives for the leaking state, as each steam trap occasionally discharges condensate and non-condensable gases, producing short bursts of stronger ultrasonic signals.

Operational benefits and sustainability impact

Introducing the NEON Sonic lets your maintenance teams spot and deal with individual trap failures in near real-time. Periodic audit reports often take time and highlight many faults simultaneously, whereas our sensors provide continuous insights that significantly reduce both time and cost. This capability enables proactive planning, smoother maintenance scheduling, and reduced operational risk.

Remote monitoring also limits the need for personnel to enter high-temperature or confined areas, improving overall site safety.

“Preventing steam loss can result in measurable reductions in energy consumption”

Customer data indicates that preventing steam loss can result in measurable reductions in energy consumption and emissions, key metrics for sites striving to achieve sustainability and decarbonisation goals. Consider a plant with 4,000 steam traps. Depending on maintenance frequency, the annual failure rate can range from 10% to 30%. With a conservative estimate of €8 per 1,000 kg of steam, a single leaking trap losing 384 kg daily results in a total daily loss of €1,229. Annually, this amounts to approximately €448,000.[2] This improved energy efficiency in many regions can also help companies qualify for green subsidies and incentive programmes.

Scalable monitoring for complex industrial sites

With thousands of steam traps in operation, scalability is essential. Each NEON Sonic monitors one trap, allowing customers to prioritise high-pressure or hard-to-reach systems first. The approach can be expanded incrementally, offering flexibility to balance cost, accessibility, and energy impact.

The shift from manual, reactive inspections to continuous, data-driven insights means that you, as a chemical manufacturer, are gaining better control over maintenance and energy use. At the same time, you are laying the groundwork for a broader digital transformation across your facilities.

[1] ISIS Fluid Control

[2] Figures calculated on data shared by our customer