How To Detect And Prevent Costly Cavitation Issues in Industrial Pumps

Background

One of TWTG’s customers, a global leader in the oil, gas, and renewable energy sectors, faced a challenging issue at one of their facilities. Engineers had detected sporadic, unusually high vibration levels in a pump, a classic indicator of cavitation. Pinpointing this elusive problem, surfacing only under certain process conditions, eluded traditional detection methods, which involved engineers manually taking acceleration and RMS velocity readings. These methods often missed the brief instances of high vibration indicative of cavitation.

Initially, as a temporary solution, an additional pump was added to help resolve the lack of performance when the situation occurred. However, the ongoing unsuccessful diagnosis meant this stop-gap had become a semi-permanent solution.

Drawing from TWTG’s hands-on experience with Cavitation Detection, this use case explores the limitations of conventional techniques. It demonstrates how NEON sensors offer a comprehensive digital monitoring perspective by rapidly and efficiently detecting cavitation.

To demonstrate these technological advances, we explore how using LoRaWAN technology can help industrial facilities improve efficiency while simultaneously reducing costs and enhancing safety.

The Challenge

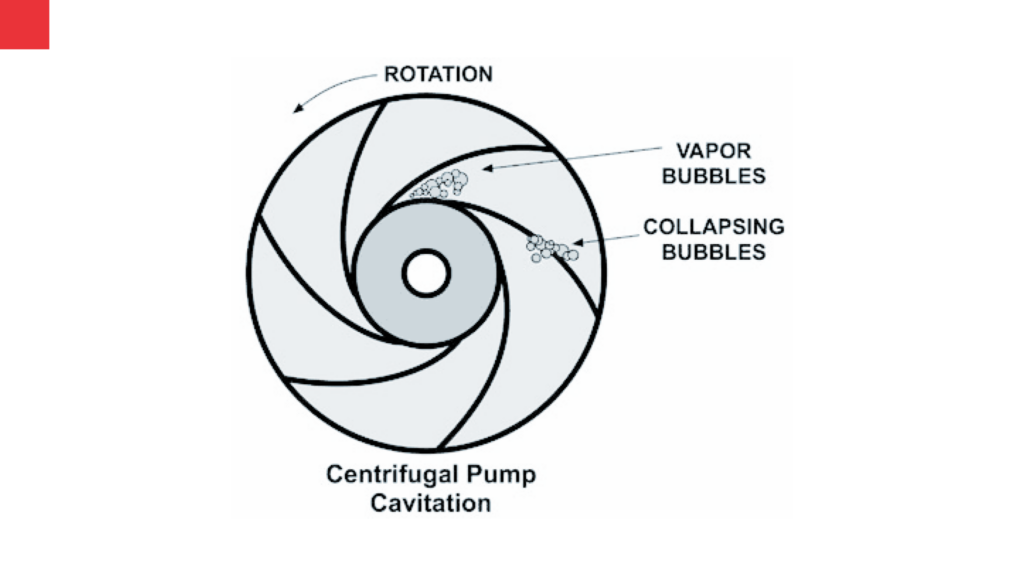

Undetected cavitation in pumps and turbines can lead to reduced efficiency, extensive equipment damage, and potentially catastrophic failures. The erosive force of cavitation wears down vital components, incurring hefty repair costs, causing unplanned outages, and disrupting energy production.

Traditional detection methods, reliant on periodic readings, often fail to capture the transient high vibration levels characteristic of cavitation. This shortcoming was particularly pronounced for our customer, whose issue manifested only under specific operational parameters. Additionally, the workaround of operating two pumps simultaneously proved inefficient, increasing energy consumption and operational costs.

“The NEON sensors quickly identified the precise cavitation occurrences, allowing engineers to swiftly implement an effective solution.”

The advent of modern, cost-effective diagnostic technologies, such as LoRaWAN-based NEON Vibration Sensors, offer a viable solution for timely cavitation detection, enhancing equipment reliability and extending its service life.

The Solution

To address the situation, the customer installed LoRaWAN-based NEON Vibration Sensors on the problematic pump. These sensors provided real-time monitoring of acceleration and RMS velocity across various operational conditions. The sensors quickly identified the precise cavitation occurrences, allowing engineers to swiftly implement an effective solution by adjusting the configuration of the surrounding plant.

Furthermore, data from the NEON sensors revealed that running the secondary pump alongside the primary one actually led to further excessive vibration. Addressing the root cause of the cavitation allowed the facility to revert to a single-pump operation, significantly reducing electricity consumption and CO2 emissions.

Products Used

- NEON Vibration Sensors – (see datasheet at twtg.io)

- SolidRed Software Suite – (see datasheet at twtg.io)

Key Benefits

Employing TWTG’s NEON solution for early cavitation detection delivered multiple advantages for our customer:

- Extended Equipment Lifespan: Early detection allowed for prompt intervention, ensuring the pump operated efficiently and maintained peak performance.

- Deeper Operational Insight: The data analysis revealed that using the second pump reduced efficiency and increased vibration of the primary pump. The resulting solution, and the removal of the second pump, brought considerable savings in electricity and CO2 emissions. This case highlights NEON Sensors’ capability to provide deeper operational insights, resulting in annual savings of approximately €300,000 in electricity and maintenance costs.

- Reduced Maintenance Costs: The NEON sensors’ ability to identify issues early on decreased the need for constant maintenance, preventing downtime and avoiding unnecessary repairs or replacements.

Following the success of this project, the customer expanded the use of NEON Vibration Sensors to other motors, gearboxes, and pumps at the primary facility and subsequently agreed to expand the full suite of NEON sensors across their global operations.

Conclusions

As highlighted in this use case, detecting cavitation in industrial pumps is a multifaceted problem. Traditional methods often fail to identify such issues accurately and promptly, leading to increased costs and operational inefficiencies. Implementing LoRaWAN-based NEON Vibration Sensors at our client’s facility marked a significant leap forward. These sensors, offering realtime and continuous monitoring capability, proved game-changing in early cavitation detection and overall pump health management.

The NEON solution not only resolved the immediate issue of cavitation for our customer but also brought about long-term operational improvements. Providing precise, actionable data has enabled smarter decision-making, reduced energy consumption, and minimized the environmental impact. The result has translated into substantial cost savings and enhanced equipment longevity – setting new standards in industrial equipment monitoring.

This success story illustrates the power of embracing advanced technology to solve traditional industrial challenges. It demonstrates the potential of digital transformation in industrial settings, where data-driven insights can lead to more sustainable, efficient, and cost-effective operations. As our client expands the use of NEON sensors across their global operations, they pave the way for a new industrial maintenance and management era.

-

View / Download as PDF

Read the Use Case in Full