You cannot manage what you cannot measure.[i] This quote from Peter Drucker essentially explains condition-based monitoring (CBM), which uses real-time data to assess the health of industrial equipment and determine when maintenance should be conducted.

It’s a simple idea that continues to unlock significant, measurable improvements. IMI TWTG’s original NEON technology range applies to hazardous environments subject to ATEX/IECEx as well as Facilities Management and Canadian Standards Association requirements, where this solution has a real impact on these dangerous sites. As initially designed, this technology gives customers the intelligence to plan and execute maintenance strategies more effectively in challenging environments.

Over time, the NEON range saved countless hours of unplanned downtime. While it’s difficult to put a definitive monetary value on this saving, the figure is likely to be high, given that even one hour offline for some facilities can run into the millions. Some of the most recognisable names in oil and gas have used the sensor range extensively. Our customer base has over 26,000 sensors installed, although their actual value extends well beyond this sector.

Existing customers report that our sensor technology has helped reduce unplanned downtime at their facility by 40% by detecting overheating and system anomalies. Manual inspections became much less necessary given that remote monitoring allowed teams to focus on the precise problem, reducing such inspections by 60%. In addition, maintenance costs were also lowered by 30% given that maintenance programmes could be scheduled proactively.

We are now making this technology available to non-hazardous sectors that do not require time-consuming certification approvals. So, the non-Ex variants of our NEON sensors are now available for use across various sectors, from pulp and paper to the automotive industry and safe areas such as manufacturing as a whole.

Coming to terms

For the uninitiated, or those simply looking to improve how their assets are run and maintained, the range of terms used to discuss I-IoT can seem like a barrier to entry. The list below will be familiar to those working in hazardous environments such as oil and gas. However, some terms may seem unclear to others, as they refer to the same thing.

Now that our NEON technology is available for you in several different sectors, it’s essential to clarify the meaning of the acronyms and initialisms we use to discuss our technology.

- Condition-Based Monitoring (CBM): This involves using real-time data to assess equipment health and determine when maintenance tasks should be performed. It’s a key part of developing an effective predictive maintenance strategy.

- Anomaly detection: Cloud diagnostics uses time series data to automatically set alarm triggers and define the ‘good’ state of the monitored asset.

- LoRaWAN: a wireless communication protocol for low-power, long-range communication in I-IoT applications. You can read more about LoRaWAN here.

It’s about better asset visibility

Our original ATEX-approved NEON devices are manufactured with robust materials and components that, as detailed above, have proven successful in various hazardous industries. NEON is now available for use in non-hazardous environments, so all the functionality and features of this range can be carried over to facilities in non-hazardous environments.

A range of businesses will benefit from this change, not least those in power, automotive, paper and pulp, food and beverage, and general manufacturing. This will be potentially transformative for those relatively new to this way of working and those with an existing sensor network that needs updating.

Where NEON makes the difference

A number of devices make up the NEON range. Here, we’ll go through those in more detail.

- NEON Vibration Sensor non-Ex Variant

- NEON Temperature Transmitter non-Ex Variant

- NEON Pressure Sensor non-Ex Variant

Each of the three products above shares some common benefits:

The first is a long battery life. We have invested in LoRaWAN technology because of its low power capabilities. Devices of this kind can operate on a single charge for long periods, which is significant for remote or hard-to-reach locations.

A longer battery life also lowers the total cost of ownership. Once installed, it will work as intended until new batteries are required. And that is usually only necessary after several years, sometimes after a decade in operation.

The second benefit common to all NEON devices is scalability. At one time, we would install 50-150 sensors at a customer’s site. At this volume, it’s critical to have a non-invasive means of updating devices.

This is where ‘over-the-air updates’ come in. Put simply, we use network connectivity to make key firmware changes remotely. IMI TWTG was the first company to do this at a commercial scale.

NEON Vibration Sensor non-Ex Variant

Vibration sensors have existed for decades. However, many installed today only measure frequencies between 10Hz and 1kHz.

At this range, you can detect some basic faults (e.g., misalignment), but not more complex issues, such as bearing lubrication issues and cavitation, which can remain undetected. This leaves sites running assets almost at the point of failure, leading to production losses or extended periods of downtime in the worst cases.

To combat this uncertainty, the NEON Vibration Sensor non-ex-Variant operates from 0.5Hz to 6.6kHz, allowing users to measure a full range of fault signatures. This better visibility ultimately allows sites to intervene more effectively.

IMI TWTG’s non-ex Variant sensor technologies use edge connectivity; each measurement comprises 26K samples over the full frequency range. This is used to generate a detailed Fast Fourier Transform (FFT) Spectrum, and an envelope spectrum is utilised to determine the type of fault. All analysis is performed on the sensor; no additional cloud computing is required. The Machine Fault Indicator reduces the requirement for vibration experts to perform manual analysis of Spectrum to determine the fault. The NEON sensor will indicate the following faults:

- Bearing Faults

- Common faults such as misalignment and looseness

All data transmitted from the sensor is open. We supply all decoders and help documentation to integrate this successfully into your existing software platforms. If an end-to-end solution is required, then we can provide our flexible SolidRed technology.

Competing LPWAN designs will typically share time series data. This alerts site teams to a problem but does not pinpoint the exact issue. With a full spectrum, however, it’s much easier to determine the cause of a fault, eliminating the requirement for further manual tests.

LoRaWAN wireless communication enables flexibility by integrating real-time data and alarms into existing communication strategies. If more detail is required, IMI TWTG can supply SolidRed software that provides visualisation, including detailed reports over the asset life cycle. SolidRed Variancloud offers connectivity for all vibration analysis requirements in a central, secure database, reports, alarms, and configuration at any time, anywhere.

SolidRed Features:

- Self-serve platform makes registering new assets, sensors and facilities easy.

- Additional detailed vibration analysis is available as standard, as well as viewing and comparing spectrums and adding spectrums to machine fault reports.

- Two-way communication with sensors, Smart Triggers, FFT Spectrum, and Harmonic Envelopes can be set or requested.

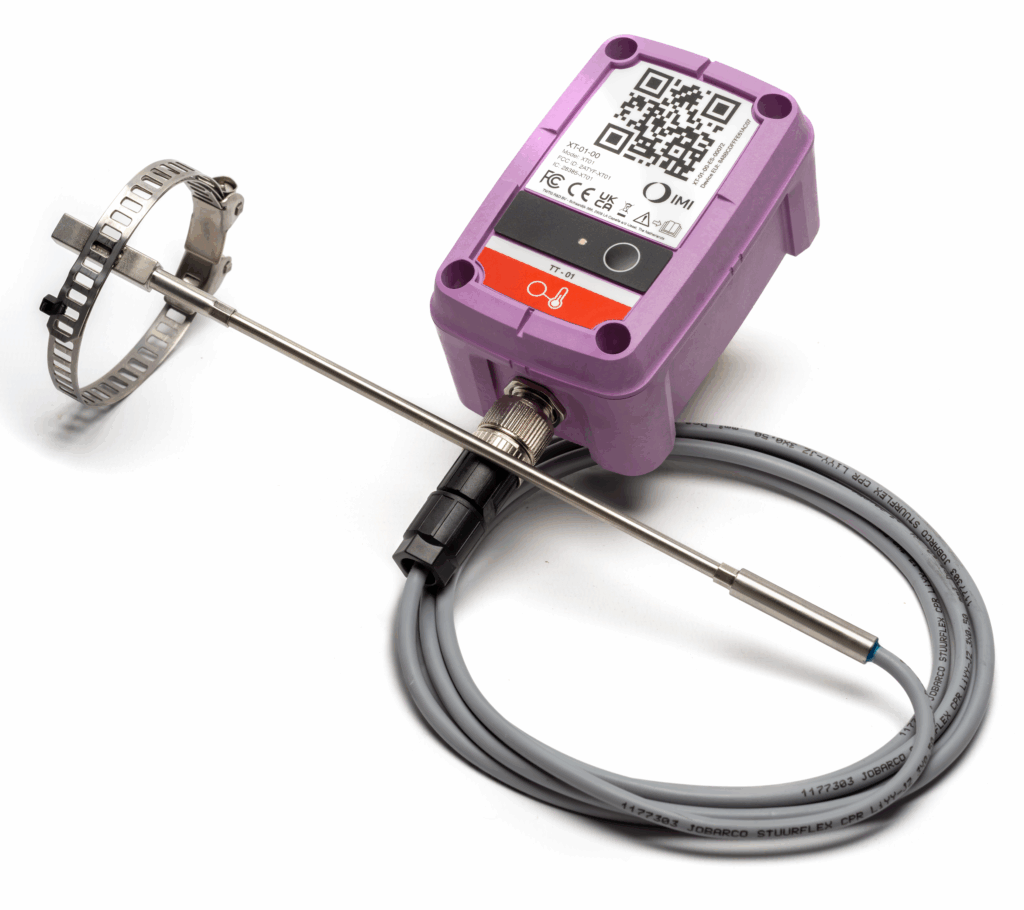

NEON Temperature Transmitter non-Ex Variant

This device is designed to make extreme temperature data visible remotely. Like our vibration sensor, it has a battery life of up to 10 years, and it’s mainly designed for threshold temperature checks. If an asset falls outside specific parameters, it will immediately alert users.

Part of what makes this device so valuable is its ability to work in a wide temperature range. Using existing or new external RTD or Thermocouples, it can monitor extremely low temperatures, like those found when working with hydrogen, as well as very high temperatures, such as those found in blast furnaces.

Temperature measurement is typically used in control loops and alarm indication within the site Scada or DCS; however, gaps in data are still present. For many sites, each product line consists of operational skids. The transfer of product from one skid to another is often overlooked. These transfer pipes can be chilled or heated depending on the application. Ineffective heating can cause issues with high-viscosity materials, resulting in blockages and production stoppages.

The NEON Temperature Transmitter non-Ex Variant sensor can be quickly added to the process. LoRaWAN gateways with built-in servers can integrate data into scada via MQTT or OPC UA.

If you’re an OEM, the NEON Temperature Transmitter non-Ex Variant can be used with SolidRed to notify all your global assets of temperature issues instantly.

You can read more about this device here.

Where this device works well:

- NEON Temperature Transmitter non-Ex Variant supports connectivity for 2 PT100, making it ideal for monitoring temperature differential across assets such as Steam Traps, Valves, & Heat Exchangers

- NEON Temperature Transmitter non-Ex Variant can be supplied with a non-intrusive temperature sensor, reducing the installation cost.

- NEON Temperature Transmitter non-Ex Variant uses time synchronisation to an accuracy of 13mSec. Ideal to understand how a complete process is working for a given time. Many other LPWAN sensors do not deploy this technology.

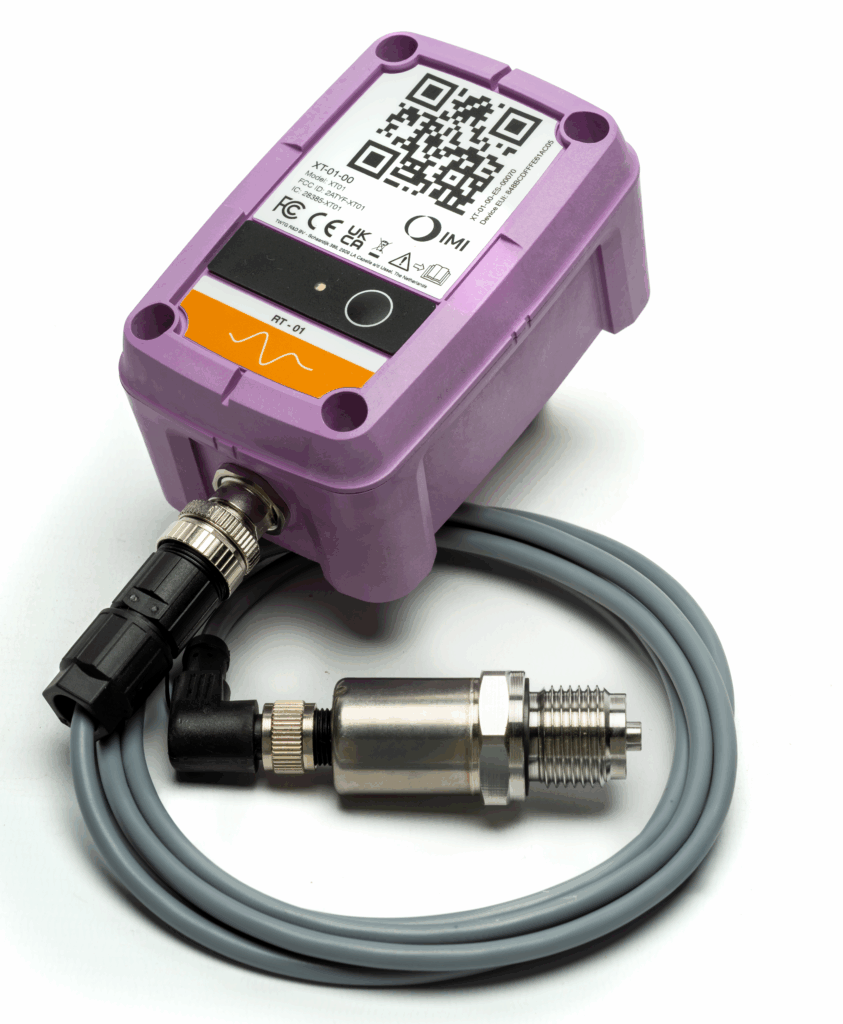

NEON Pressure Sensor Non-Ex Variant

Our pressure sensor uses the same technology and gateway infrastructure mentioned above. However, recognising the safety-critical nature of pressure checks in all facilities, this device also has the option to fit a Badotherm gauge for engineers seeking immediate confirmation of an asset’s status. This device can be easily retrofitted.

Where this device works well:

- Help eliminate manual rounds for routine pressure checks.

- Designed to replace existing mechanical measures with supplemented digital reading that continues to work during a plant stoppage.

- Ideal for burst pipe detection for remote parts of your plant.

Why this all matters

Many sectors still rely on manual, infrequent asset inspections, and this reactive approach leaves critical equipment exposed to undetected faults between checks. Addressing this issue demands a fundamental shift in how industrial uptime is managed. IMI aims to drive that transformation by offering a fully integrated solution that blends reliable hardware, intelligent analytics, and LoRaWAN connectivity.

This enables companies to seamlessly adopt continuous, real-time condition monitoring with minimal disruption, empowering operational teams to transition from reactive maintenance to predictive strategies that save time and money.

Sources

[i] What Peter Drucker Really Meant by “If You Can’t Measure It, You Can’t Manage It” — And How Agile Teams Can Use Cycle Time to Improve Delivery – Red Spanner