How NEON Sensors in Refinery’s Industrial Cooling Water System Prevent Clogging

Background

This document aims to comprehensively detail the design, implementation, and impact assessment of the advanced temperature monitoring system integrated into a circulated cooling water system (CWS) of our customer, a major refinery. It emphasizes the strategic decision-making processes, technological innovations, and operational enhancements brought about by this approach.

The refinery’s CWS, a critical component for maintaining efficient production, faced increasing challenges in adapting to the evolving demands. Initially designed for a specific operational capacity, the system struggled to integrate new heat exchangers, leading to a noticeable decline in water distribution. The lack of adequate water pressure led to the gradual accumulation of residue, which resulted in increased clogging and occasional blockages. These challenges ultimately compromised the efficiency and reliability of the CWS.

The Challenge

The refinery confronted several interlinked challenges:

- Inadequate Water Distribution: Especially at distant and higher points in the system, the water flow and pressure were significantly lower than the design specifications intended, leading to inefficiencies in cooling.

- Increased Deposit Formation: Due to the inefficient operation of both air and water coolers, there was an increase in deposit formation within the system, impeding heat transfer and raising concerns over potential long-term equipment damage.

- Operational Inefficiency: These challenges collectively threatened the refinery’s operational efficiency, with a looming risk of equipment shutdowns, increased maintenance demands, and potential replacement costs.

The Solution

Responding swiftly to the emerging challenges, the refinery’s engineers demonstrated remarkable agility, demonstrating a solid understanding of the latest innovative techniques. Only 3 hours after receiving the business

“Only 3 hours after receiving the business request, the team installed 4 TWTG NEON Temperature Sensors at a key water cooler.”

request, the team installed 4 TWTG NEON temperature sensors at a key water cooler. Integrated into an advanced data management system, the sensors enabled real-time, comprehensive monitoring of water temperatures at cooler inlets and outlets. This technological advancement provided unprecedented insight into the CWS’s performance, marking a significant step forward in the refinery’s operational management.

Measurements – How It’s Done

The effectiveness of the solution was measured through a systematic approach:

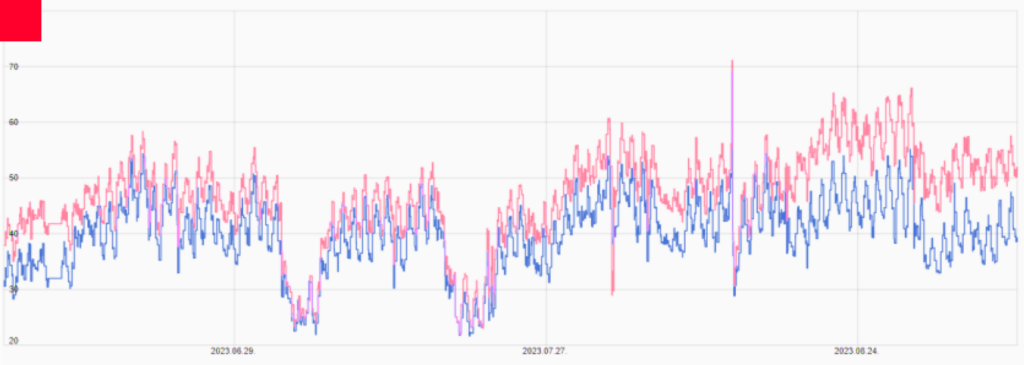

Data Collection: The sensors provided continuous temperature data, capturing minute-by-minute changes in the system, as well as aggregated data.

Performance Analysis: Utilizing an advanced analytics tool, the collected data was thoroughly analyzed, comparing real-time performance data against established efficiency benchmarks and historical performance metrics.

Predictive Insights: The system’s capability to analyze trends in the data enabled the refinery to move towards a predictive maintenance model, identifying potential issues before they become critical

In August 2023, the refinery experienced a process upset, resulting in a critical increase in water temperature detected by the temperature sensors. The temperature surged above 70°C, a significant deviation from the operational norm. This rise was critical as it affected the efficiency of deposit prevention chemicals, which became less effective above 60°C.

The analytics tool’s analysis of this data allowed for a clear visualization of the water cooler’s efficiency degradation. In response to this data, swift actions prevented potential long-term operational damage and maintained system efficiency. Following this incident, continuous monitoring has been instrumental in the overall health of the CWS. The ongoing data collection facilitated predictive maintenance, reducing unplanned maintenance activities and improving heat transfer efficiency.

Products Used

- NEON Temperature Sensors – (see datasheet at twtg.io)

Conclusions

The implementation of this temperature monitoring solution has significantly improved the CWS’s management, enhancing system reliability, reducing maintenance costs, and ensuring continuous operational efficiency.

Key Benefits:

- Operational Efficiency: Improvement in overall efficiency by approx. 5%.

- Maintenance Reduction: Reduction in unplanned maintenance activities by around 15% annually.

- Predictive Maintenance: Increase in predictive capabilities by 20%, allowing for more timely interventions.

- Data-Driven Decisions: Informed decisions leading to a 10% reduction in operational costs.

- Cost Savings: Hypothetical annual savings of approximately $300,000 from reduced maintenance and operational improvements.

-

View / Download as PDF

Read the Use Case in Full