Optimizing Industrial Lubrication with NEON Vibration Sensors

Background

In the industrial sector, managing the operational status of rotating equipment like pumps, gearboxes, and fans is crucial for maintaining efficiency and safety. Any rotating device with the potential for metal-on-metal contact can suffer a high rate of failure if not correctly maintained, highlighting the importance of effective lubrication management.

Historically, assets have been monitored at intervals, often monthly, with manual vibration measurement. While helpful in managing unexpected downtime, this traditional approach is highly labor-intensive and often fails to catch potential issues in time, risking catastrophic failure. The advent of advanced monitoring technologies promises to address these challenges, offering more reliable and continuous oversight of these critical assets.

The Challenge

A primary challenge in industrial maintenance is the correct choice and application of lubricants. This is said to account for around 40% of all machine failures. Thus, lubrication procedures are a critical factor in maximizing equipment reliability. It’s widely accepted that monthly manual checks are primarily inadequate for capturing all potential issues, posing risks of catastrophic failures.

For an engineer to deliver optimum lubrication, it is essential to use the right type and quality of lubricant, in the correct amounts, applied at the right place and time. The gap in traditional monitoring methods, like periodic manual vibration measurements, leaves a significant window where lubrication faults can go undetected, leading to equipment damage or failure. This highlights the need for a more effective and continuous monitoring solution to promptly identify and prevent lubrication-related issues.

The Solution

TWTG’s NEON Vibration Sensors offer a revolutionary approach to monitoring lubrication in industrial equipment. These sensors are installed on bearing housings of critical machinery, transmitting RMS velocity values at frequent intervals for continuous monitoring.

“Sensor data can be reviewed via TWTG’s SolidRed analytics platform, allowing for precise detection of lubrication faults.”

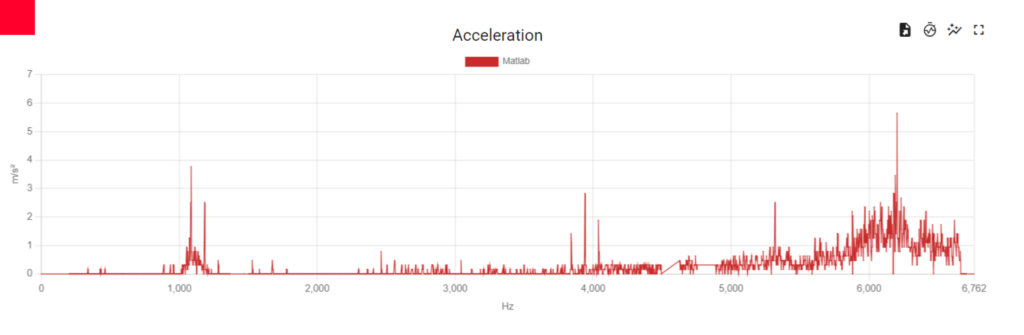

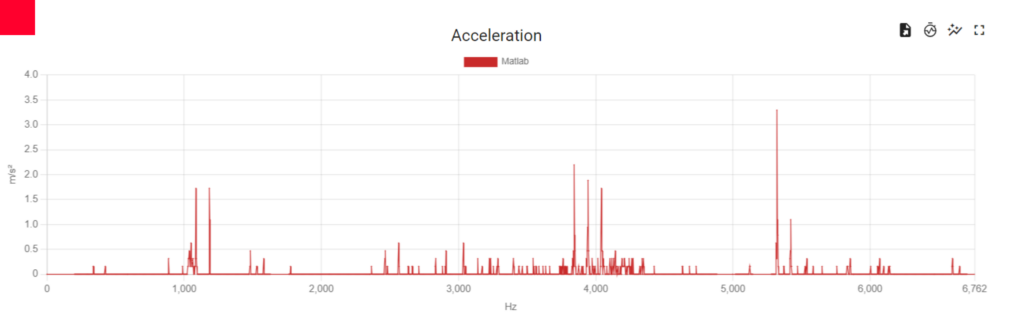

This method is a significant advancement over traditional monthly inspections, providing real-time insights into equipment condition. By transmitting bi-daily full FFT measurements, sensor data can be reviewed via TWTG’s SolidRed analytics platform, allowing for precise detection of lubrication faults.

Measurement – How It’s Done

NEON Vibration Sensors measure the condition of assets by continuously tracking RMS velocity and acceleration data. Anomalies, such as sudden drops in vibration levels post-lubrication, are flagged for immediate inspection. This approach contrasts with traditional methods by providing ongoing monitoring and detailed spectral analysis, enabling early detection of over-lubrication and other lubrication faults before they escalate.

Products Used

- NEON Vibration Sensors – (see datasheet at twtg.io)

- SolidRed Software Suite – (see datasheet at twtg.io)

Key Benefits

Benefits of using TWTG’s NEON Vibration Sensor with SolidRed to detect and prevent lubrication faults:

- Enhanced early detection of lubrication faults reduces the risk of equipment failure.

- Significant labor and cost savings by replacing manual, periodic checks with continuous, automated monitoring.

- Improved operational efficiency and safety through real-time, data-driven maintenance decisions.

- Insight into optimum lubrication levels extends the lifetime of assets.

- Full FFT measurement for deeper analysis and micro-level insights.

- 5Hz to 6.6 KHz bandwidth unique in preventative solutions.

Conclusions

The implementation of TWTG’s NEON Vibration Sensors marks a significant improvement in detecting and preventing lubrication faults in industrial machinery. This technology not only enhances the reliability and efficiency of equipment but also significantly reduces labor and downtime associated with traditional monitoring methods. NEON Sensors combined with SolidRed makes continuous, automated monitoring possible and makes visible what was previously unseen.

-

View / Download as PDF

Read the Use Case in Full