Revolutionizing Predictive Maintenance with NEON ActiveMFI Technology

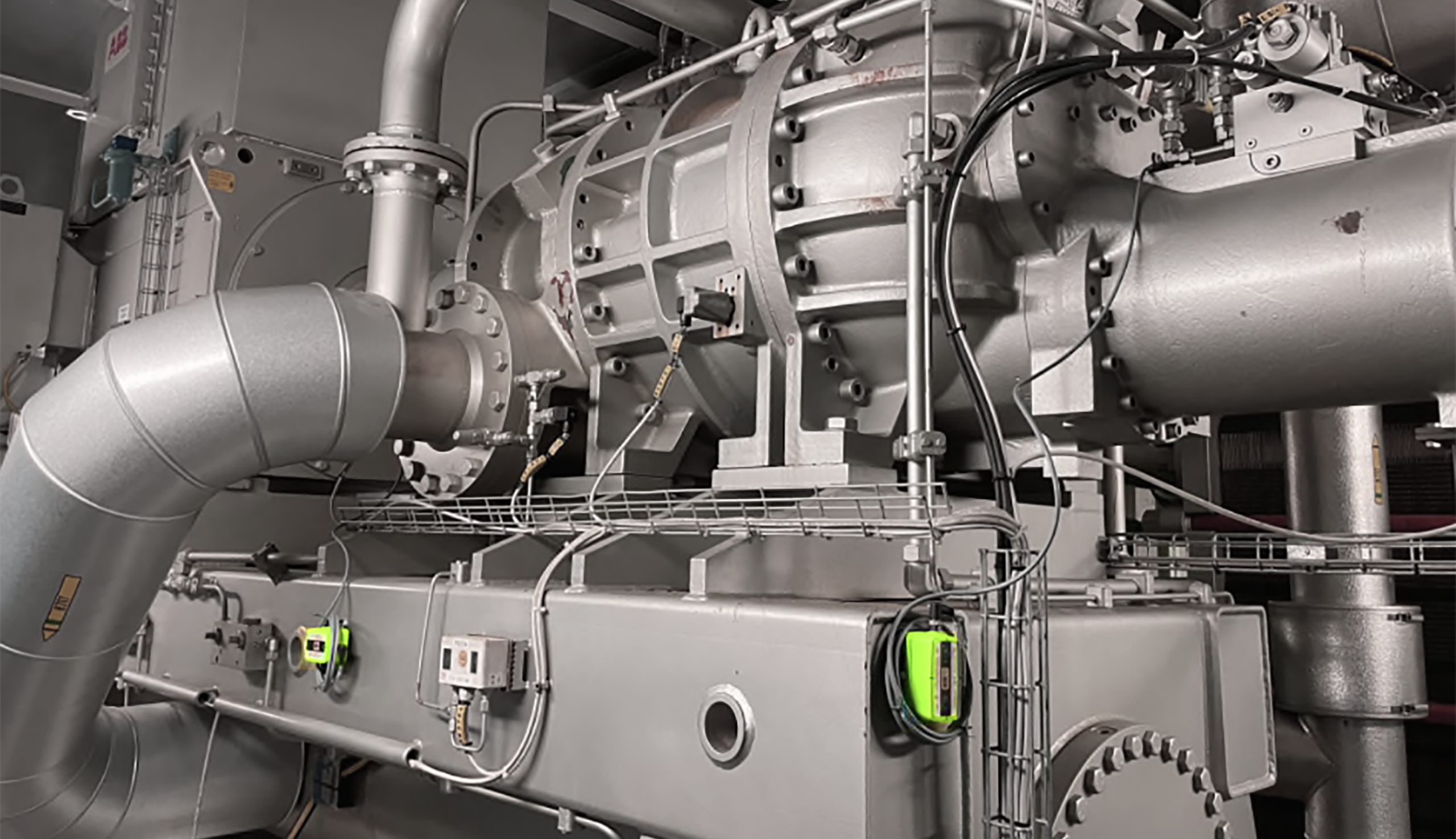

In a modern industrial plant, the reliability and performance of every piece of machinery are crucial in avoiding unscheduled, costly downtime. Modern Technologies, particularly the Industrial Internet of Things (I-IoT) and predictive maintenance, are leading the way in keeping facilities operational.

In this trajectory, TWTG developed its sensor fusion technology, featuring innovations like TimeSync and EventSync—features designed to orchestrate and synchronize multiple sensors to provide new levels of insight and predictability. Now, following these, is a further advanced innovation – ActiveMFI (Machine Fault Indicator).

ActiveMFI: A Game-Changer in Predictive Maintenance

ActiveMFI represents a significant leap forward in terms of agility and precision. The NEON sensor continues to perform its standard monitoring role, but now, with ActiveMFI, it can perform precise fault detection and data analysis, issuing alerts when necessary—all without being part of a broader analytic network.

Imagine a large modern facility with thousands of wireless sensors, each sending data to be processed and analyzed at a central location. Until recently, engineers have had to run analytical software and analyze frequency data for each device, actively searching for anomalies and breaches that are tell-tale signs of forthcoming faults.

With NEON sensors running ActiveMFI, the device itself performs the analytics. Each device, via machine learning, learns its own breach limits and historical data, working independently to predict faults and issue alerts. Data can still be sent to a central analytic point – such as TWTG’s SolidRed analytics suite – to achieve a holistic view of operations, increase overall efficiency, and take advantage of advanced multi-sensor analysis, such as SolidRed’s EventSync.

Key Features of ActiveMFI

ActiveMFI is able to detect a full range of machine-learned faults, including but not limited to:

- Advanced Vibration Analysis: Enhanced vibration analysis capability utilizing sophisticated sensors and algorithms to detect even the slightest anomalies in machine behavior.

- Bearing Fault Detection: Identifies both early and late-stage bearing faults through specific frequency patterns.

- Rotor Unbalance and Bent Shaft Detection: Measures deviations in the rotor’s mass distribution and identifies shaft deformations causing uneven rotation.

- Eccentricity and Soft Foot Detection: Detects misalignment issues and improper mounting conditions leading to excessive vibrations.

- Misalignment Detection: Identifies both angular and parallel misalignments between connected shafts.

- Mechanical Looseness and Resonance Identification: This technique detects components that are not securely fastened and identifies resonance conditions that amplify vibration.

Comprehensive Data Analysis

ActiveMFI offers detailed insights into machine health with comprehensive data analysis features, including:

- Harmonic Frequency and Amplitude Measurement: Measures and reports on harmonic frequencies and their amplitudes, clearly showing machine health.

- Advanced Algorithms and Statistical Analysis: Analyzes vast amounts of vibration data to identify patterns and correlations indicating potential issues.

User-Friendly Fault Diagnosis and Recommendations

ActiveMFI automatically determines faults and advises the end-user on root causes and corrective actions. This significantly reduces the required level of technical knowledge, enabling informed maintenance decisions quickly and effectively.

Transforming Remote Facility Maintenance

ActiveMFI is a transformative technology for remote facilities. With possible minimal technological monitoring or even a sophisticated monitoring solution hosted thousands of miles away, ActiveMFI brings cutting-edge technology to remote locations without requiring complex and costly installations. A sensor that detects a fault can immediately alert a local engineer of operational changes. The engineer can then take appropriate action or request assistance for further analysis and recommended steps. This results in swifter action, ultimately reducing downtime and maintenance costs.

Implementation and Availability

While firmware for new NEON Vibration Sensors will include ActiveMFI, an installable upgrade will be made available for existing devices, allowing engineers to take full advantage of this innovative solution. Sensors without ActiveMFI technology will be unaffected and continue to function normally.

Experience the Future of Predictive Maintenance

At TWTG, we are committed to providing innovative solutions that enhance the reliability and performance of industrial machinery. Our new ActiveMFI technology represents a significant leap forward in predictive maintenance. By leveraging advanced vibration analysis, real-time monitoring, comprehensive data analysis, and a user-friendly interface, we empower our customers to maintain optimal machine health and operational efficiency.

Experience the future of predictive maintenance with TWTG’s ActiveMFI technology. Contact us today to learn more and schedule a demonstration.