Background

Steam Traps, common yet essential components in the process industry, are too often prone to failure, leading to wasted energy and increased costs. To prevent these issues, steam traps must be monitored regularly to detect and address malfunctions. Traditional steam trap monitoring methods involve manual inspection and testing, which can be time-consuming, labour-intensive, and, unfortunately, prone to human error.

This use case, built on our industrial experiences with Steam Trap Monitoring, considers the challenges of traditional monitoring methods and analyses how recent technological advancements have opened up the possibility of achieving a complete digital monitoring overview.

To demonstrate these technological advances, we explore how using LoRaWAN technology can help industrial facilities improve efficiency while simultaneously reducing costs and enhancing safety.

The Challenge

Steam trap degradation and failure is a frustratingly frequent problem in the process industry. An effective monitoring procedure can certainly help mitigate failure and avoid energy wastage. Yet, until very recently, the cost of individually monitoring the hundreds, if not thousands, of steam traps within a busy facility was simply unfeasible.

However, today, this situation has completely changed. Recent technological advances and vastly reduced costs now make total monitoring possible.

Leading the way, LoRaWAN Temperature-Based Detection has entirely revolutionised steam trap monitoring, which can now be effectively achieved by the simple and swift installation of wireless NEON Temperature Transmitters.

The Solution

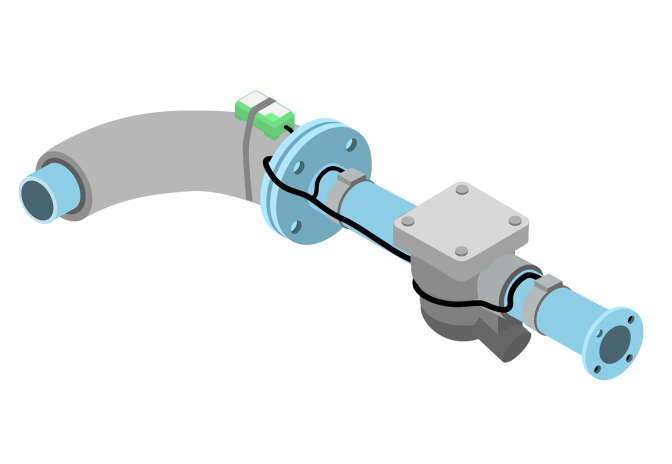

A pair of NEON wireless Temperature Transmitters create an ingenious monitoring solution for steam traps. These seamlessly work together to identify anomalies and react to determine the first signs of a fouled trap. As well as immediately restoring efficiency, this swift action dramatically extends the lifespan of the trap, as well as bringing a vast reduction in overall energy waste to the facility.

“A pair of NEON wireless Temperature Transmitters create an ingenious monitoring solution for steam traps.”

A LoRaWAN network requires minimal infrastructure and can be easily integrated into existing systems. The retrofittable sensor solution fits nicely with the LoRaWAN backhaul. Easily deployable in an active environment, sensors can be installed without any wireless path planning or complex wiring. For the engineer, it’s simple – Just mount and forget. The system will activate a LoRaWAN sensor over the air, and the data will start coming in.

Measurement - How It’s Done

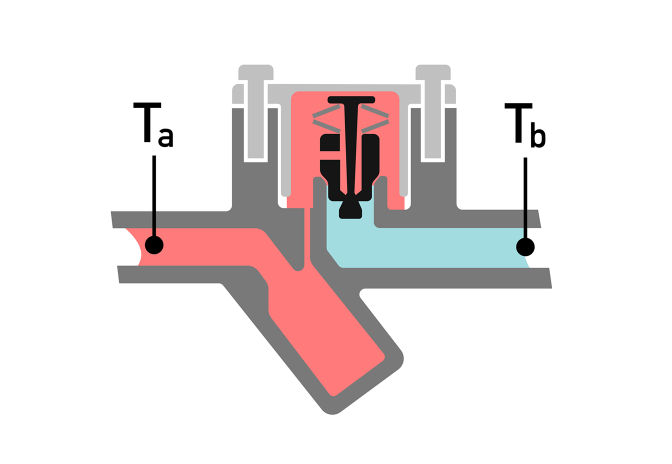

Two PT100 temperature probes attached to a TWTG Temperature Transmitter can effectively detect steam trap failures in almost any industrial application. By installing the probes upstream and downstream of the trap and simply measuring the temperature difference, the solution can identify two types of failures: blocked traps and failed open traps.

Blocked Steam Trap Detection:

When a steam trap is blocked or clogged, it hinders steam flow, resulting in reduced or no steam flow to the downstream side. As a consequence, the downstream temperature will be lower than expected. The system continuously monitors the temperature difference between the two PT100 probes to detect a blocked steam trap. If the temperature difference falls below a pre-set threshold, it indicates that the steam trap is blocked, triggering an alert or alarm.

Failed Open Steam Trap Detection:

When a trap fails to open, steam can pass through even when not needed, leading to excessive steam reaching the downstream side. As a result, the downstream temperature will be higher than it should be. To identify a failed open steam trap, the temperature transmitter compares the temperature difference between the two probes to a predefined threshold. If the temperature difference exceeds this threshold, it indicates that the steam trap has failed open, and the system sends an alert or alarm.

Products Used

- 1 NEON Temperature Transmitter – (see datasheet at twtg.io)

- 2 PT100 probes

Key Benefits

Benefits of implementing NEON sensors for steam trap monitoring:

- Early detection of steam trap degradation, enabling preventative maintenance and avoiding costly steam leaks and inefficiencies.

- Significant energy savings potential, up to 20% reduction on a facility’s annual energy bill.

- Improved safety within the facility by promptly addressing faulty steam traps and minimising the risk of accidents and injuries.

- Reduced maintenance costs as continuous monitoring eliminates the need for time-consuming and labour-intensive manual inspections.

- Decreased gas emissions by optimising steam trap efficiency and reducing unnecessary energy consumption.

- Simple retrofitting of NEON sensors to existing equipment for smooth integration into any facility.

Conclusions

The use case outlines how steam trap monitoring using TWTG’s NEON Temperature Transmitter and PT100 probes presents a cost-effective and efficient solution to detect and prevent costly steam trap faults. These wireless LoRaWAN sensors allow facilities to continuously monitor without requiring extensive wiring or frequent battery replacements.

The benefits are substantial. It allows for the early detection of steam trap degradation, enables preventative maintenance, and avoids costly steam leaks and inefficiencies. This proactive approach can lead to significant energy savings, with potential reductions of up to 20% on a facility’s annual energy bill.

In conclusion, implementing TWTG’s NEON Temperature Transmitter and PT100 probes for steam trap monitoring offers a comprehensive, wireless, and energy-efficient solution. The benefits of continuous monitoring include substantial energy savings, improved safety, reduced maintenance costs, and decreased gas emissions. This technology represents a significant advancement in steam trap monitoring, paving the way for enhanced efficiency and sustainability in industrial settings.

TWTG’s NEON range of LoRaWAN sensors offer continuous monitoring and are simply retrofitted to existing equipment. A combination of devices can be utilised to address the most common use cases. Alternatively, for industrious engineers, sensors can be innovatively deployed to produce unique, tailored insight for particular scenarios.