Background

At Shell Energy and Chemicals Park Rotterdam, our customer Shell works on the energy of today and tomorrow. On this vast site, the largest refinery in Europe, crude oil is refined to high-grade fuel. Holland Hydrogen One, a 200-megawatt electrolyzer that produces green hydrogen, is being built by Shell close by.

Assets on these sites, from pumps to heat exchangers, are monitored for safety, and operational and environmental efficiency. A LoRaWAN network and thousands of TWTG’s NEON Sensors enable all assets, critical and non-critical, to be digitalized for better, data-driven decisions. It makes the site a global frontrunner in enhancing safety and efficiency via digital transformation.

How do they do it?

The Challenge

At Shell Energy and Chemicals Park Rotterdam, there are aging as well as state-of-the-art technologies such as a dedicated pipe line to the green hydrogen site. In particular the 50-year-old assets lack information that our customer would like to have more data on in order to optimize processes and make data-driven decisions.

The Solution

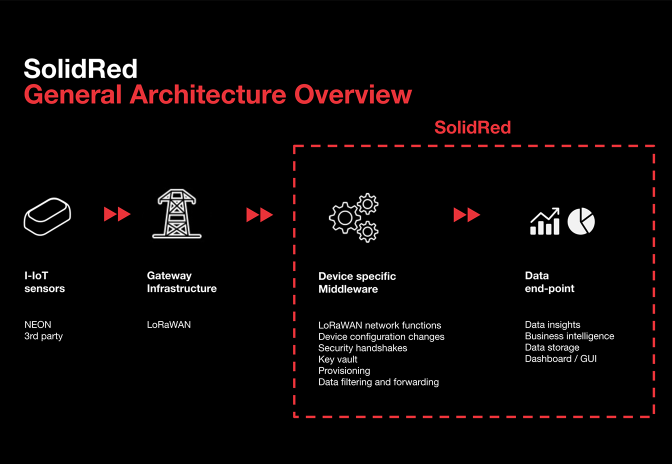

Deploying SolidRed Software Suite in addition to NEON IIoT devices on a LoRaWAN network provides a comprehensive solution to these challenges. The use of a LoRaWAN network and TWTG’s ATEX / IECEx-certified NEON devices enables better, data-driven decisions, making the customer a global frontrunner in enhancing safety and efficiency via digital transformation. LoRaWAN and NEON Vibration, Pressure, and Temperature Sensors are chosen by our customer to monitor thousands of assets on sites like these. NEON Sensors are easy to install and use. Condition monitoring for critical and non-critical assets is now the norm on this vast site, reducing downtime and manual rounds.

Wino Spix, Shell’s IIoT Focal Point / Instrument Engineer at the Park, explains: “We use the sensors as a flexible add-on to our existing install-base of

We gain multiple benefits that we were previously unable to get. It enables our engineers and technologists to work data-driven and to make better decisions.

wired instrumentation because the flexibility of LoRaWAN and low network costs give us the possibility to measure everywhere on our site, which was previously impossible. We gain multiple benefits that we were previously unable to get. It enables our engineers and technologists to work data-driven and to make better decisions.“

Deploying SolidRed Software Suite in addition to NEON devices on the LoRaWAN network provides a comprehensive solution to the challenges, offering continuous, real-time monitoring of 1,000s of assets, enabling early detection of potential issues. The smart software makes sense of the data generated by the devices, organizing and visualizing the bits and bytes into full spectrum analyzes.

Rodney Meivogel, Rotating Equipment Inspector at Shell Energy and Chemicals Park Rotterdam receives actionable insights in his control room using data from 1,000s of wireless NEON Vibration Sensors and SolidRed Software Suite. He says “Because much more data is now coming in than before with hand held analyzers, we are able to detect anomalies even earlier and prevent major repairs. That is the biggest benefit we gain from using NEON Vibration Sensors.“

Measurement - How It’s Done

NEON Sensors are TWTG’s market-leading IIoT sensors, based on LoRaWAN technology. They are wireless, battery-powered, retrofittable, and ATEX / IECEx-certified for use in the most demanding hazardous environments. Asset monitoring data gathered by these devices is sent and received via a LoRaWAN network. All that’s basically needed for the sensors is a LoRaWAN network infrastructure and a gateway.

SolidRed is the IIoT Software Suite from TWTG, designed to unleash the potential of IIoT sensors far beyond their basic functionality. SolidRed works seamlessly with TWTG’s retrofittable NEON LoRaWAN Sensors. Whether an entire facility or its individual assets, SolidRed provides profound insight into the workings of a site. As a monitoring tool, SolidRed operates 24/7/365, receiving precise, regular measurements from assets. A combination of pre-defined conditions and machine learning means SolidRed continually analyzes data and then, when necessary, issues alerts.

SolidRed can monitor an entire site at this level but every customer’s solutions are different, and so, if required, data can be forwarded to the customer’s preferred analytical solution. At Shell Energy and Chemicals Park Rotterdam, SolidRed operates on Shell’s IRMS platform.

Products Used

- NEON Vibration Sensors – (see datasheet at twtg.io)

- NEON Temperature Transmitters – (see datasheet at twtg.io)

- NEON Pressure Sensors – (see datasheet at twtg.io)

- SolidRed Software Suite – (see datasheet at twtg.io)

Key Benefits

- Better, data-driven decisions thanks to large-scale IIoT deployment using a LoRaWAN network, NEON Sensors, and SolidRed Software Suite

- Remote monitoring: no more manual operator rounds with hand-held analyzers, but only when a deviation is detected

- Enhanced safety and operational efficiency, with preventing machine failures as one of the biggest benefits

- Smart software monitors and visualizes trends: SolidRed combined with NEON Vibration Sensors enables condition monitoring for critical and non-critical assets

- High on ownership and flexibility, low on infrastructure and cost

Conclusions

Getting real-time information on thousands of assets on a site in order to optimize processes and make data-driven decisions, can be a real challenge. The use of a LoRaWAN network, with its flexibility and low network costs, and IECEx-certified, retrofittable, wireless NEON Sensors give the possibility to measure everywhere on site, which was previously impossible.

A LoRaWAN network and thousands of TWTG’s NEON Sensors enable all assets, critical and non-critical, to be digitalized for asset monitoring and to create actionable insights and data-driven decisions. This enables engineers and technologists to work data-driven and to make better decisions. It has made Shell Energy and Chemicals Park Rotterdam a global frontrunner in enhancing safety and efficiency via digital transformation.