Introduction

Effective battery monitoring is crucial in large-scale industrial deployments to ensure sensor networks operate continuously and efficiently. Accurate battery monitoring helps reduce downtime and maintenance costs, enabling asset managers to manage resources better and maintain operational reliability.

The Need for Accurate Battery Monitoring

- Large-scale Deployments: Replacing batteries or devices on an ad-hoc basis across extensive sensor networks is wasteful, time-consuming, and labor-intensive.

- Optimal Timing: If an engineer can accurately estimate the approximate battery life of an asset, a planned replacement can be done in batches or simultaneously with other service intervals, ensuring continuous operation without interruptions.

- Cost Savings: Accurate monitoring helps prevent early replacements, ensuring full battery utilization and minimizing costs.

Challenges with Traditional Methods

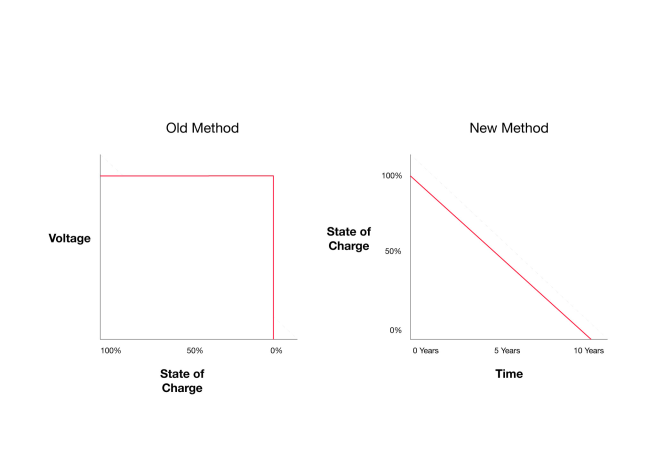

Battery Voltage Monitoring: Traditionally, the most common method for monitoring battery life has been to measure the battery’s voltage and use this measurement to estimate its remaining capacity. When the voltage drops below a certain threshold, a warning is issued, indicating that the battery is nearing the end of its life.

Limitations of Voltage-Based Monitoring: Conventional voltage-based battery monitoring methods have significant limitations. Voltage-based monitoring can be unreliable due to fluctuations caused by sensor activity and environmental factors like temperature, often leading to false alarms and inaccurate readings.

Lithium-thionyl chloride batteries used in NEON devices maintain a stable voltage throughout their discharge cycle. While lithium-thionyl chloride batteries offer stable performance, their steady voltage profile makes it difficult to predict battery depletion, potentially leading to unexpected downtime or rushed maintenance.

Due to such limitations, traditional voltage-based battery monitoring is often inadequate for ensuring the reliability and efficiency required in industrial environments. As a result, the industry is moving to embrace the latest technologies to provide more accurate and reliable solutions.

Coulomb Counting: The Advanced Solution for Battery Monitoring

To overcome the limitations of traditional battery monitoring methods, TWTG leverages Software Coulomb Counting, a well-established scientific method for measuring energy consumption. Coulomb counting provides more accurate battery life predictions, optimizes energy usage, and simplifies sensor management.

How It Works

- On the NEON Device: The Coulomb counting process is performed directly on the NEON device. This process counts the total energy consumed by tracking all energy-consuming activities—such as measurements, transmitting (TX), receiving (RX), watchdog operations, and standby mode—over time.

- Data Reporting: The device reports this energy usage data to TWTG’s SolidRed analytics suite or other compatible platforms. These platforms display the data, allowing asset managers to monitor battery status easily.

- Temperature Adjustments: The NEON device automatically adjusts energy usage calculations based on temperature changes, accounting for environmental conditions that could affect battery life.

Benefits for Asset Managers

- Ease of Use: Asset managers can access battery status data through their existing device management platforms or the LNS (LoRaWAN Network Server), providing a straightforward interface without needing in-depth technical knowledge.

- Accurate Predictions: TWTG’s sensor technology enables more precise predictions of battery life, allowing for better planning and reducing the risk of unexpected downtime.

Advantages of NEON Products for Battery Management

With new advanced battery monitoring capabilities, TWTG’s latest NEON Vibration Sensors and Temperature Transmitters provide significant advantages over other solutions. Here’s how these innovations offer superior performance and reliability:

- Enhanced Battery Monitoring with Coulomb Counting:

Coulomb counting allows for detailed, real-time tracking of energy consumption, ensuring that asset managers receive reliable data on battery status and can more precisely plan maintenance activities. - Seamless Integration with SolidRed Analytics Suite:

TWTG’s SolidRed analytics suite monitors sensors for battery life and device performance through one centralized platform. SolidRed offers advanced analytics and real-time reporting, enabling proactive decision-making and helping asset managers optimize battery management. - Improved Time Management: Accurate battery predictions enable better planning, reducing the need for frequent replacements and labor costs. By timing replacements precisely, asset managers can optimize resource allocation and focus on other critical tasks.

- Additional Benefits of NEON Sensors: With the future in mind, TWTG’s NEON sensors incorporate hardware and software capabilities to support upcoming features, such as variable battery life optimization. All NEON devices are designed for harsh industrial environments and offer long-term durability and reliability, ensuring optimal performance even in extreme conditions. By investing in NEON, asset managers can reduce maintenance costs, improve battery monitoring accuracy, and benefit from a lower total cost of ownership over time.

Battery Empty: What’s Next?

When a NEON device’s battery reaches the end of its life, there are two sustainable paths forward:

1. Recycle the Device: TWTG encourages responsible disposal by offering a return program. Once a NEON device’s battery is depleted, you can send the device back to TWTG for proper recycling. NEON devices are designed for easy disassembly, allowing us to ensure that all components, from the battery to the base materials, are recycled in the most environmentally friendly way possible.

2. Refurbishment Kits: Alternatively, TWTG offers refurbishment kits that include a replacement battery, giving your NEON device a second life. Each NEON device is built to be refurbished at least once before other components start reaching the end of their operational lifespan. This solution allows you to extend the lifecycle of your devices, reducing waste and maximizing your investment in the technology.

Conclusion

Accurate battery monitoring is vital for maintaining the efficiency and reliability of sensor networks in industrial environments. By leveraging the scientific method of Coulomb counting, TWTG provides a precise and user-friendly solution for asset managers, allowing for better planning, reduced downtime, and cost savings.

Optimize your sensor network and reduce costs today. Contact TWTG for a demonstration and discover the future of battery monitoring.